Making Cannons

My longstanding fascination with explosives was heightened about 25 years ago when I ran into a guy who owned a foundry in West Rutland (Campbell Plaster and Iron), who coincidentally let it be known that he "loved cannons", and who offered the use of his foundry for the project. One thing led to another and, finding the price of naval gun bronze to be much lower in large quantities, I decided to build eight cannons instead of just one. Several friends became "investors" in the project. These are the basic steps involved:

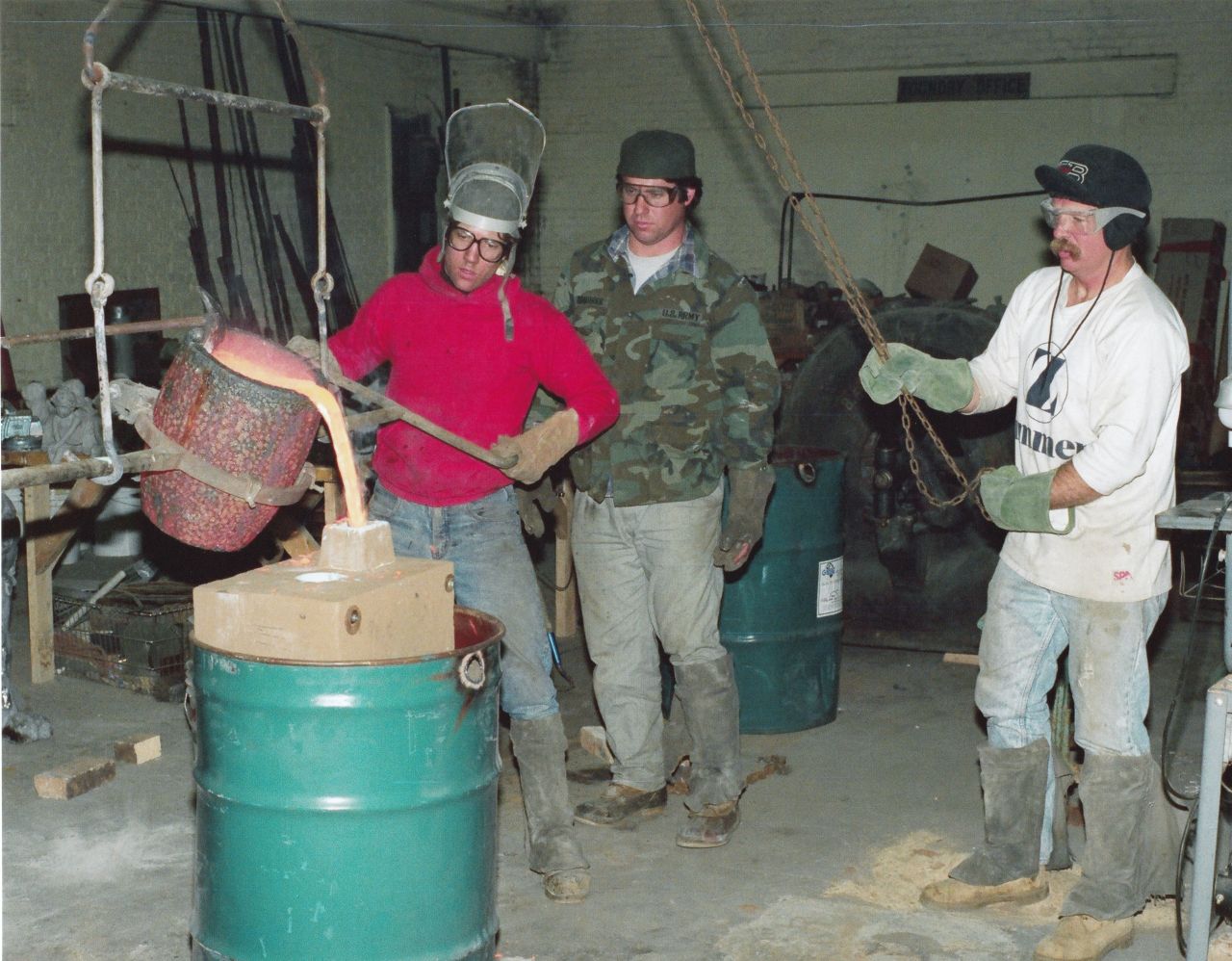

1. A wooden pattern is made that can be split to create a sand mold, one half at a time, so that the halves can be vented and then reassembled to hold the shape of the cannon when the void is filled with molten bronze.

2. Bronze ingots are melted in a crucible, then poured into the sand mold. It takes a day for it to cool sufficiently to even handle.

3. The vent tube and other excess bronze is cut from the cannon, which is a solid casting that needs to be bored, so they were all loaded (each weighing 100 pounds) into my car and taken to the "Hole Specialist" in Palmer, Massachusetts to have them center-bored. It's no coincidence that the bore size was that of a golf ball, or a one pound lead cannonball. After the boring, the weight of each one was reduced to 70 pounds.

4. Seven of the "tubes" were test-fired with twice the normal powder charge and two stacked cannonballs. The 8th tube was packed with five times the normal powder charge and five lead cannonballs, effectively making it a bomb rather than a cannon, and we were able to recover all five cannonballs and most of the cannon fragments.

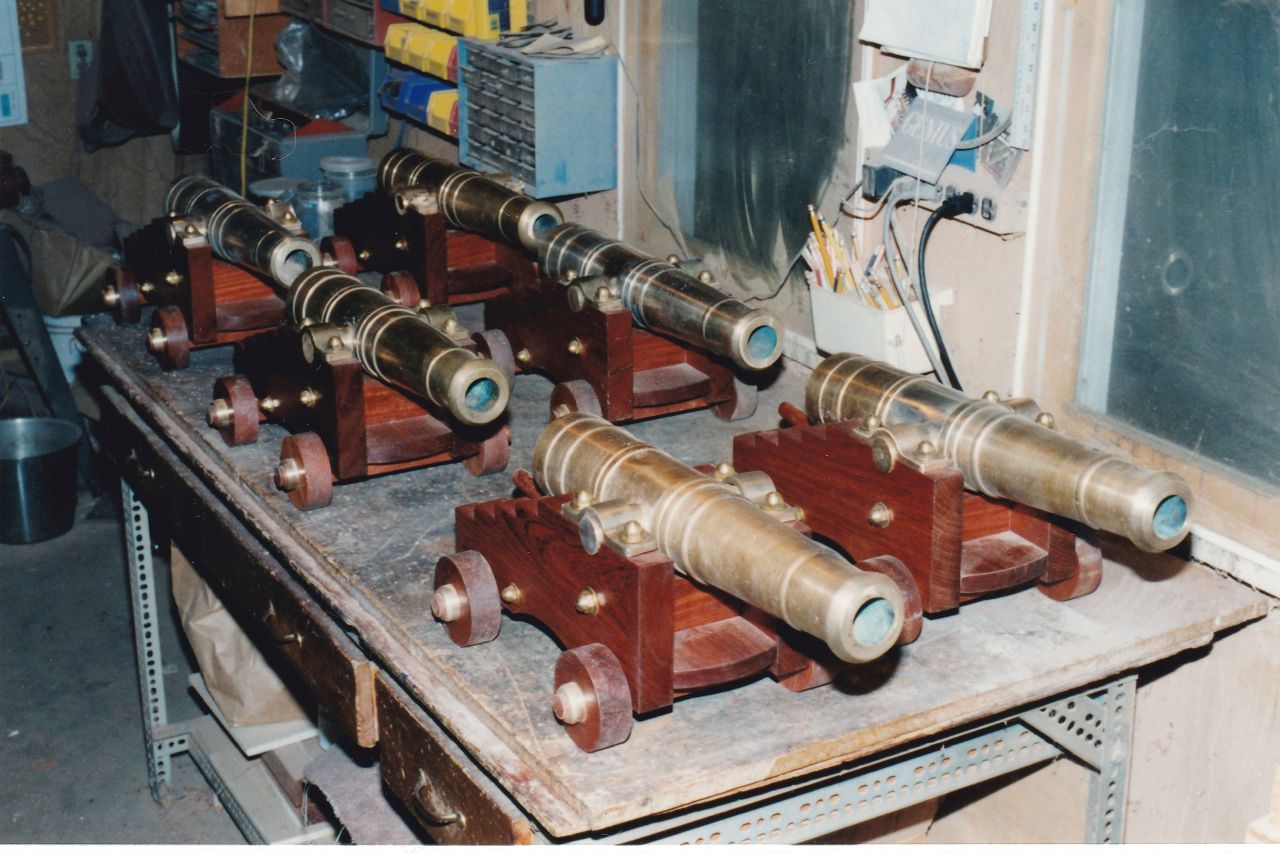

5. Once bored and test-fired, I had to smooth the entire exterior surface of each cannon by making a vertical turntable device, then sanding and polishing the bronze.

6. The leftover bronze was used to make the additional hardware, which involved a whole separate sequence of pattern making, casting and polishing.

7. Carriages and wheels were fashioned from heavy African Bubinga that I had acquired in a separate woodworking project.

8. Now used primarily for making noise, they're still capable of shooting a cannonball a distance of approximately three miles.

DHB 7/14/19

This machine at the "Hole Specialist" took about half an hour to drill from muzzle to breech and was accurate to a few thousands of in inch.